This is the Cosmic's soldering robot system.

We believe stabilizing the heat is important to improve the accuracy of soldering and stabilize it.

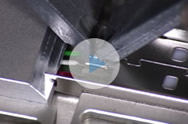

The PSU500(robotic soldering) has achieved the quantification by cutting the solder and using ceramics on the soldering tip so that the melted solder would not adhere to it.We are using a ceramic heater which has the heating element inside almost top of it for stable heat supply.

By our idea, the PSU500(robotic soldering) has achieved high-temperature immediate soldering (Operating temperature approximately 550 to 600°C.)

But the temperature of the solder and electronic components will never reach 600°C.

Soldering iron is useful only by hand tool, It's Cosmic thinking.

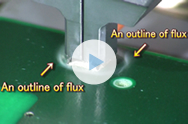

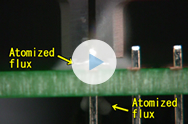

Flux is atomized immediately when it contacts the high-temperature heater. In our automated point soldering robot system (PSU-500), “Atomized Flux” (flux is atomized immediately on contact with high temperature) is always applied to the component before melted solder arrives.

Click the photo on the above to watch the video.

PSU500(robotic soldering) can extremely reduce the time for spending maintenance & adjustment on daily, weekly and monthly because all soldering data is digitized (NC control).

Soldering for PCB

Soldering for PCB

Soldering for Micro RF Connector

Soldering for Micro RF Connector

.Soldering for D-sub connector & Cable

.Soldering for D-sub connector & Cable

PCB and coaxial cable

PCB and coaxial cable

Thermister and wire

Thermister and wire

FPC and plastic terminal wrapped up pre-solder wire

FPC and plastic terminal wrapped up pre-solder wire

USB(Standard A)

USB(Standard A)

UEW wrapped terminal

UEW wrapped terminal

Multicore cable to aluminium PCB

Multicore cable to aluminium PCB

Solid wire to PCB

Solid wire to PCB

The same amount of solder

The same amount of solder

Slow motion for atomized flux (for spreading)

Slow motion for atomized flux (for spreading)![Terminal to PCB [pitch of 1.27mm]](images/common/videos_thm_30.jpg)

Terminal to PCB

Terminal to PCB

Slow motion for atomized flux (for through-hole)

Slow motion for atomized flux (for through-hole)

Coaxial cable to central conductor

Coaxial cable to central conductor

Direct thin copper wiring to component

Direct thin copper wiring to component

Stripped cables to through-hole PCB

Stripped cables to through-hole PCB

Stripped cables to lead switch

Stripped cables to lead switch

SMD for surface soldering

SMD for surface soldering

Joint of stripped cables

Joint of stripped cables

Power terminal to through-hole PCB

Power terminal to through-hole PCB

Lead wire to angle terminal

Lead wire to angle terminal

Terminal adjustment component

Terminal adjustment component

Lead wire to connector

Lead wire to connector

Connector terminal

Connector terminal

Lead wire connector “type of insert”

Lead wire connector “type of insert”

Joint to PCB (vertically)

Joint to PCB (vertically)

External conductor of coaxial cable

External conductor of coaxial cable

Bridge soldering “moving sideways”

Bridge soldering “moving sideways”

Joint to PCB (45°)

Joint to PCB (45°)

Cables to PCB

Cables to PCB

UEW wires

UEW wires

Through-hole

Through-hole

Cable to registor

Cable to registor

Cable to terminal

Cable to terminal

SMD connector to PCB

SMD connector to PCB

Piezoelectric element

Piezoelectric element

FPC to terminal

FPC to terminal

Quartz oscillator

Quartz oscillator

Stable increment for soldering amount

Stable increment for soldering amount

Terminal to PCB in the plastic box

Terminal to PCB in the plastic box

Terminal to PCB

Terminal to PCB